HOJU sheet metal working

Cutting:

With our CNC guillotine shears we can cut sheets with a thickness of 0.5 – 3.0mm and a width of up to 3000mm.

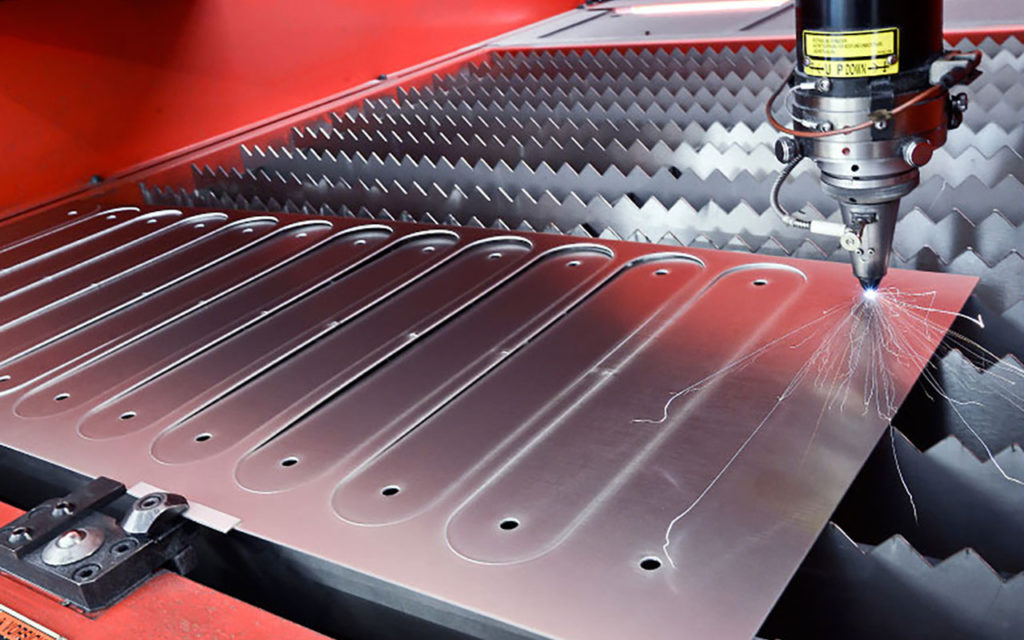

Laser cutting:

Our CNC laser system cuts precisely stainless steel up to 10mm and aluminium up to 8mm material thickness in the dimensions 1500 x 3000mm.

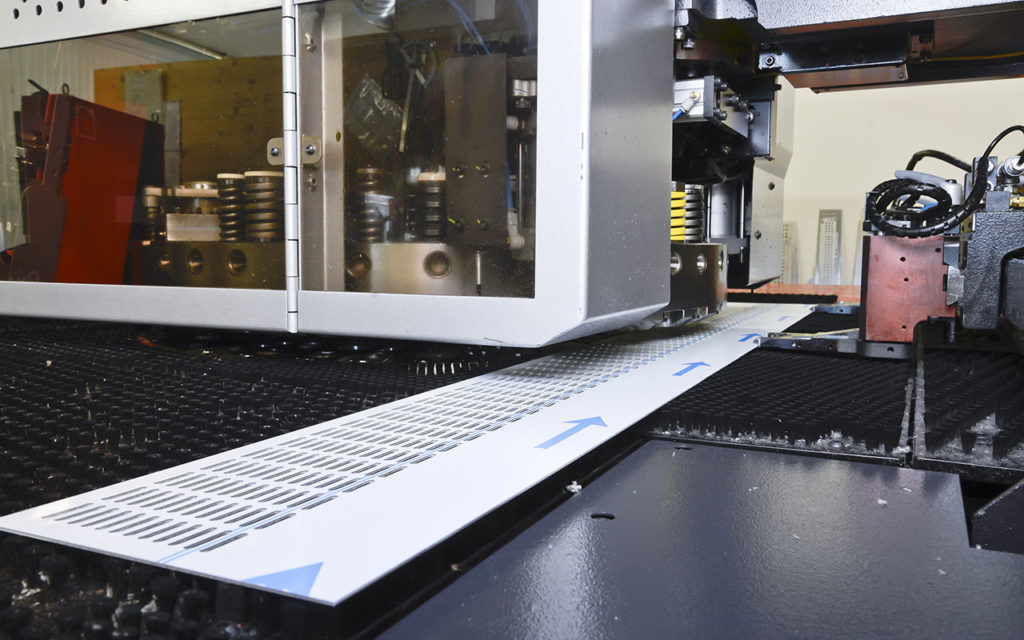

Punching:

The CNC punching nipple machine punches holes and shapes, makes embossing and draws through with an automatic tool change system. Sheets up to 3mm material thickness and in the dimensions 1250 x 2500mm can be processed.

Straightening:

The automatic roll straightening machine is able to straighten parts and minimize tensions caused by the punching and laser processes. The maximum processing width is 1250mm.

Grinding:

With our wet grinding machine we can deburr, grind and brush surfaces. The maximum processing width is 900mm. This machine can also be used to create grinding patterns and satin finishes on the surface of parts.

Bending:

Two CNC-controlled bending machines and a mechanical swivel bending machine are available. With these machines it is possible to bend formings up to 170 tons press force and lengths up to 3000mm.

Welding:

We use a spot welding machine to join components, with which sheets can be joined together, inseparably and hardly visible. We also have a CNC-controlled stud welding machine and a hand-guided stud welding gun with which we can weld threaded studs and bushes.