HOJU Profile processing

Sawing:

With our automatic sawing machine we can cut aluminium profiles to length fully automatically. For smaller quantities and special orders we also have a semi-automatic cross-cut saw available.

Notching:

Our two semi-automatic special machines notch the rear webs on the profiles to ensure that the profiles fit perfectly. It is also possible to punch a hole in the webs.

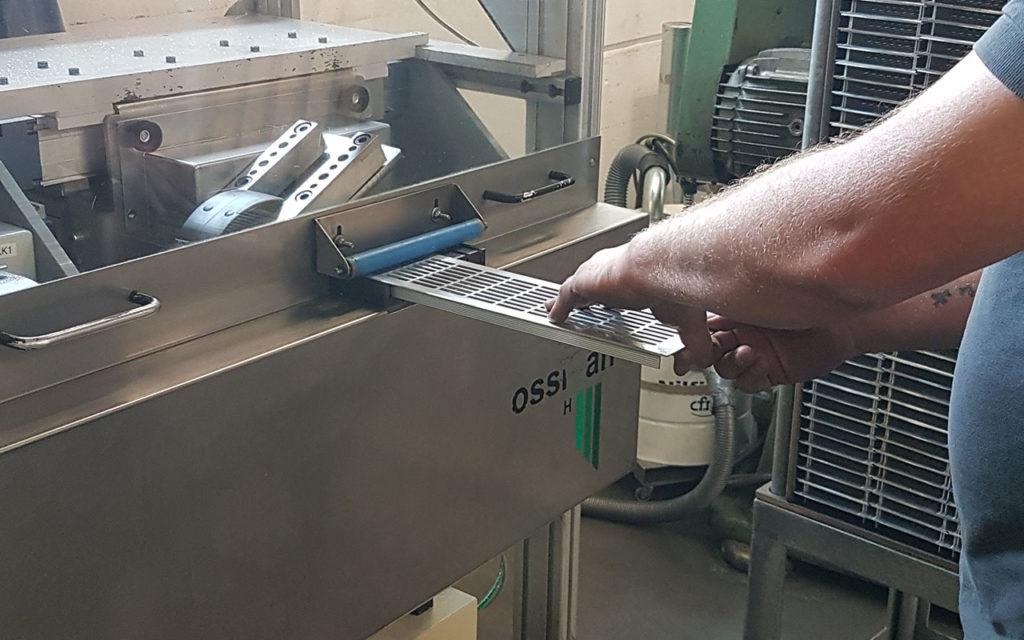

Punching:

Our five eccentric presses are used to punch the holes in our web plates. This is possible in automatic mode or manually. Depending on the perforation, presses with 40, 60 or 100 tons press force are available.

Chamfering:

With our semi-automatic chamfering and milling machine and our two grinding machines, the front sides of our profiles are chamfered in a handy and visually pleasing way.

Surface treatment:

Our subsequent surface treatment of the web plates ensures a great look and a wear-resistant surface. You can choose from various anodised colours and the entire RAL colour range for powder coating.